Wood frame construction and fire are a deadly combination! It’s easy to understand the concern...

STI News

Sustainable building practices have reached a fever pitch. Programs such as LEED and Living Building Challenge are helping us to make our buildings greener. Our focus as a society has changed significantly in the last 20 years, and we are witnessing the advent of a new type of construction material – wood. Well, wood is not new, but the way we are building with wood is certainly changing. You may have heard of CLT – and then again maybe you have not. Cross-Laminated-Timber (CLT) is not exactly new, but it is new to us Americans. As many things do, the trend of building with CLT started in Europe, primarily in Scandinavia, and has finally made its way westward. That explains why the predominant suppliers of CLT to date are from that area of the world – but times they are a changin’. CLT has a number of sister materials, such as Glue Laminated Timber (GLT), Nail Laminated Timber (NLT), Dowel Laminated Timber (DLT), Laminated Strand Lumber (LSL), Parallel Strand Lumber (PSL), Laminated Veneer Lumber (LVL), and Mass Plywood Panel (MPP). These materials are all considered mass timber materials, but to keep things simple, the most popular material of these is CLT.

are helping us to make our buildings greener. Our focus as a society has changed significantly in the last 20 years, and we are witnessing the advent of a new type of construction material – wood. Well, wood is not new, but the way we are building with wood is certainly changing. You may have heard of CLT – and then again maybe you have not. Cross-Laminated-Timber (CLT) is not exactly new, but it is new to us Americans. As many things do, the trend of building with CLT started in Europe, primarily in Scandinavia, and has finally made its way westward. That explains why the predominant suppliers of CLT to date are from that area of the world – but times they are a changin’. CLT has a number of sister materials, such as Glue Laminated Timber (GLT), Nail Laminated Timber (NLT), Dowel Laminated Timber (DLT), Laminated Strand Lumber (LSL), Parallel Strand Lumber (PSL), Laminated Veneer Lumber (LVL), and Mass Plywood Panel (MPP). These materials are all considered mass timber materials, but to keep things simple, the most popular material of these is CLT.

If you have not seen CLT before, it is much like plywood but on a much grander scale. The plys are typically about ¾ inch in thickness, and are laminated together in alternating 90 degree directions. This gives the panel significantly more strength than just standard lumber. Advocates for CLT cite the economical and environmental advantages to that form of construction vs. traditional concrete. The 2018 Edition of the International Building  Code® (IBC) includes an entire chapter on mass timber construction, and CLT projects are being proposed in many areas. As of the 2018 IBC the tallest wood structure allowed in the code is 6 stories. The 2021 IBC cycle is near completion and the new code will introduce three grades of Type IV (Heavy Timber) construction. Type IV-A is the most robust, IV-C is the least, and IV-B is somewhere in the middle. For Occupancies A2-4 (Assembly), B (Business), R1-4 (Residential) that are categorized as Type IV-A and are sprinklered – that limit has increased to 18 stories. Did I mention that times are changing?

Code® (IBC) includes an entire chapter on mass timber construction, and CLT projects are being proposed in many areas. As of the 2018 IBC the tallest wood structure allowed in the code is 6 stories. The 2021 IBC cycle is near completion and the new code will introduce three grades of Type IV (Heavy Timber) construction. Type IV-A is the most robust, IV-C is the least, and IV-B is somewhere in the middle. For Occupancies A2-4 (Assembly), B (Business), R1-4 (Residential) that are categorized as Type IV-A and are sprinklered – that limit has increased to 18 stories. Did I mention that times are changing?

There has been a lot of work to understand how larger buildings constructed of mass timber and CLT would perform, and certainly fire safety has been a key concern. There has been work devoted to understanding how these systems would behave under fire exposure conditions, including the structures themselves and the supporting elements. Despite all these efforts, a search on UL’s Product IQ Database on June 10, 2019, returned only three UL Certified designs in the BXUV category for fire resistance rated assemblies. Those designs establish the ratings for the various configurations of CLT wall or floors, including where additional design features such as gypsum board are required.

Clearly, more work needs to be done to understand fully how these systems will perform. Features such as fire

doors and fire-rated glazing must be tested and Certified. Penetration systems need to be tested and Certified. Even curtain wall facades need to be tested with CLT to determine how such systems will impact CLT when significant portions of the wall are damaged by fire or even the radiant heat generated from fire exposure comes into play.

into play.

Nevertheless, CLT is coming and the firestop industry knows that sooner or later Certified systems will be needed to address the various penetrations that will be made into CLT assemblies. There has been a lot of discussion within industry meetings such as the IFC with UL and other third-party laboratories as we discuss the next steps towards generating listings.

STI has done preliminary research about penetrations in CLT. We have even gone so far as to issue engineering judgments (EJs) based on the internal testing we have performed. We are still waiting to see how labs such as UL will handle these Certifications. Nevertheless, our research has proven a few key things:

- Encapsulating the assemblies with gypsum board improves the fire-ratings and has an ameliorating effect on the firestop system performance.

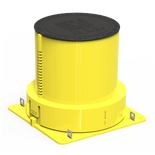

- For plastic pipe systems, firestop collars are an excellent choice because they fully choke off the pipe and stop fire from getting into the assembly.

- Where collars are used, we have seen better results in using longer screws to ensure that the devices are screwed into a portion of the timber that is beyond that which is exposed and will char.

- Metallic pipes, conduits, or tubes, insulated pipes, and cables are pretty easily handled with firestop sealant and mineral wool as would be the typical firestop system installed into a concrete floor. But, you won’t find many of these systems without that protective insulation in place, and point contact systems will prove to be very difficult.

STI’s Engineering Services team stands ready to assist on CLT projects. We look forward to the industry and third-party labs such as UL developing the criteria to test and list penetration firestops in CLT. There is still work to be done, but in time, we are confident that testing and industry collaboration will yield the right answers.