Departments at Baptist Health had hired contractors to do above-ceiling work at several different...

STI News

Maintaining barriers in health care facilities can be an arduous process if the plan is no plan at all. With so many different trades and departments having access to the barriers, identifying and repairing infractions can be a challenge unless facilities have a plan to address barrier management. Barrier management can come with a cost. But having a proactive protocol to barrier management will save an organization time and money.

So, what are the tools needed in building a successful barrier management program?

Having a complete standard operating procedure (SOP) is a good start. These documents should include all policies and protocols that are expected to be followed by anyone who is accessing a barrier for inspection or remediation. A full overview of what is expected must be spelled out such as: procedural requirements, performance requirements, submittal requirements, and installation requirements. This document is provided as part of the contract or bid documents to any trade or firm surveying barriers or installing firestop. The SOP should have strong language about the expectations and the consequences for failing to comply!

A major element of the SOP is the need for permitting of all parties entering the barrier. The permit should include information like who, what, where, when, and how the surveys will be conducted and the penetrations sealed.

In addition, worksheets of installed systems need to be completed and recorded once the project is completed. These documents should have information such as the system installed, who installed it, and the location of the penetration. A worksheet becomes an effective inspection tool for the facility staff to use in ensuring barrier maintenance compliance. This process also provides accountability for the work performed.

Labels specifying information about penetration firestopping (who, what, where, and when a penetration was firestopped) provide the essential information needed during inspection. While creating the labels may seem like just one more task to complete, these labels are a great way to push installer accountability. If someone signs their work for all to see, they may take more care in the application.

Another aspect of having an SOP is the standardization of UL systems that are used in the facility. Having the number of typical systems narrowed down can make the process of inspection much easier. A series of appropriate systems would be selected by the facility staff with assistance from a firestop authority for all the different trades and types of penetrations. The contractor/installer would be only allowed to select from preselected systems. If an installation is not covered in the standard systems, approval would be required from the person in charge of the barrier management program. Standardizing systems will help ensure the facility is getting what has been preselected and not what is in the best interest of the installer. During product selection, consider whether this is the most cost-effective sustainable application, if the penetration will need to be reentered over time as needed when dealing with many cable applications, and whether the application requires movement capabilities.

As with any written protocol, the SOP will fail to have any effectiveness without a solid training program. Training on the expectations of the SOP should be required of anyone who installs, inspects, or designs firestop systems. The training must be comprehensive and cover all aspects of the SOP, from selecting the preselected system to be installed, to understanding the patient environment in which the work is being performed, and to closing out the work on completion. It’s more than simply, “Red caulk goes here!”

A Success Story

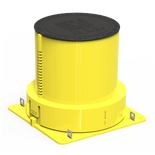

UC Health—Medical Center of the Rockies in Loveland, Colo., has worked hard to maintain its barriers. Staff and contractors working in the facility attend barriers annual training to review firestopping products and installation procedures. The facility uses a maintenance free fire-rated pathway for high traffic openings to ensure proper cable management and compliance with policy and procedures.

The facility has used a barrier management program since it started using UL systems, and has established an above-ceiling permitting process for all of our vendors. One key to the success of the program is buy in and follow up from facility staff. The facility makes sure all vendors are aware of the firestop standard operating procedure and that they adhere to the above-ceiling permitting process each time they are in the facility.