Maintaining Fire and Smoke Seals within the structured cabling pathway is an ongoing challenge,...

STI News

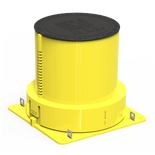

Every device in the EZ-Path Family takes a keep it simple approach to maintaining Air Leakage Seals, providing exceptional ratings without exception, interpretation, or user manipulation.

Maintaining reliable air leakage seals between compartments is not just a good idea but also is required in Building and Life Safety Codes. With sealants that dry or cure and penetrants such as piping that never change after initial installation air leakage seals are fairly straight forward; that all changes when it comes to structured cabling that by design need to be modified on a regular basis. Traditional conduit sleeves with putty can easily be left non-compliant when putties are not reinstalled after cable moves occur. Your typical 4” conduit sleeve left unsealed can allow for as much as 131.9 CFM of air leakage; that’s more than double the maximum allowable leakage in a 10 x 10 foot wall or floor area per the International Building Code® (IBC), which caps air leakage at 50 CFM per 100 square feet of wall or floor area.

EZ-Path doesn’t suffer from reinstallation issues when it comes to maintaining air leakage seals. Each device in the EZ-Path Fire-Rated and Smoke & Acoustical Pathway families self-seal as cables are added or removed from the cable pathway. When it comes to EZ-Path there is no requirement for putties, bags, or twisting of constrictive seals to maintain Air Leakage seals.