In this issue:

STI News

When it comes to versatility and firestopping, many thoughts come to mind. The ubiquitous red caulk that we see liberally applied on construction projects is obviously very versatile. Versatility in the sense of firestopping is defined as being able to adapt or be adapted to a variety of applications. While firestop caulk is used in a variety of different applications, those applications tend to be fairly consistent (i.e. sealing of penetrants traversing fire-rated assemblies).

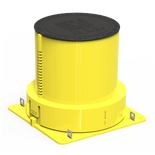

When I think about versatility, the product that comes to mind is the firestop pillow, and more specifically the SpecSeal® Firestop Pillow. And while there are many different types of pillow products on the market today, there are some inherent properties associated with our pillow that makes me feel confident in proclaiming it to be the most versatile.

When I think about versatility, the product that comes to mind is the firestop pillow, and more specifically the SpecSeal® Firestop Pillow. And while there are many different types of pillow products on the market today, there are some inherent properties associated with our pillow that makes me feel confident in proclaiming it to be the most versatile.

Pillows are an excellent choice for a variety of applications. They are certainly a great choice for large openings with mixed or multiple penetrants. They offer the added benefit of allowing the installer to work from a single side of the wall or floor. This is ideal for applications in shaft walls where access is restricted to the finished side of the wall. It is also ideal for situations where access is restricted to one side such as a fan coil unit, electrical cabinet, or switch gear sitting atop an opening in a floor. When it comes to retrofit, they are well suited to the task. If you have to add services, such as new cabling, simply pop a pillow out, run the new cable and replace the pillow.

Pillows can accommodate some degree of movement due to their resilient nature. They are also fast to install. Having spent over two decades in this industry, I have encountered many contractors who prefer pillows because they allow them to get the job done so much faster than other competitive methods.

While I am certainly biased towards the SpecSeal® Firestop Pillow, I do think it has its advantages. The obvious is the fact that we coat all six sides of the pillow with intumescent material. This is an advantage because our systems tend to use less putty or sealant than competing systems. Some competitive pillows only have intumescent on top and bottom. A quick review of the associated UL Systems proves they tend to use more putty or sealant as a result. There is a competitive pillow that features full encapsulation. However, the coating is applied via a dipping process, which makes it quite heavy, and that impacts the ability of the product to be compressed and quickly recover. We provide four different sizes. The advantage of the largest size is its space filling capabilities, but the nice thing about the smallest size is its compressibility to be installed into tighter areas!

There are some people who like foam bricks. To some, those products seem like they would outperform pillows. But I am still a firm believer in the power of pillows. I have yet to see someone seal an opening with foam bricks faster than they would with pillows. Sadly, most of the installations we see in the field for foam bricks fail to resemble the marketing collateral associated with said products. When spaces get tight, they are just too difficult to compress and the higher coefficient of friction for the foam makes them exceedingly challenging to install. Pillows produce a lot less smoke than foam bricks under fire conditions, and that is very important to me when I consider how much surface area could be exposed in larger openings.

So, if you have not tried a pillow, it is probably high time. They are great for banks of conduit, cable tray openings, fan coil cabinets, switch gear, or openings in shaft walls. Their higher cost compared to conventional fire caulking products is easily offset by the speed and efficiency with which they can be installed. If you are a committed foam brick user; give the pillow a try on your next project. Call our Engineering Services team if you have any questions.